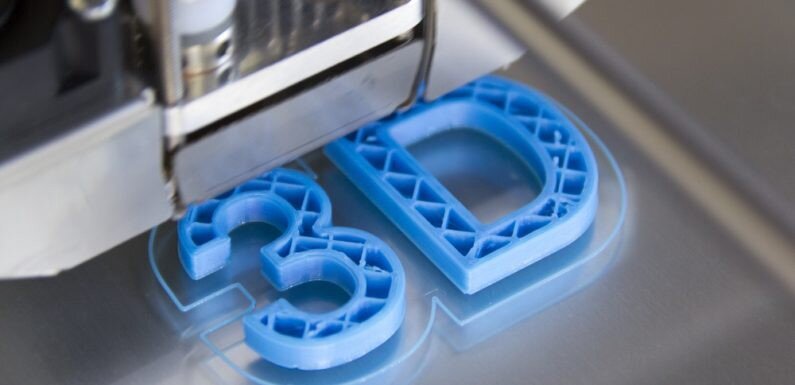

3D Printing & Rapid Prototyping Services

3D Printing Overview

3D printers use computer-aided design (CAD) to create 3D objects from a variety of materials, like molten plastic or powders. Unlike what you would see in science fiction shows, 3D printers act somewhat similarly to traditional 2D inkjet printers, use a layering method to create the desired object. They work from the ground up and pile on layer after layer until the object looks exactly like it was envisioned.

3D Printing Materials

Fused Deposition Modeling (FDM) is probably the most used form of 3D printing. It’s incredibly useful for manufacturing prototypes and 3d printer models with plastic. These printers have extreme flexibility in what can be printed. They can use plastics to print rigid materials or to create flexible objects using a hybrid rubber/plastic powder. Some 3D printers even have the ability to print with carbon fiber and metallic powders for extremely strong industrial products. Here are some examples of different materials:

Acrylonitrile butadiene styrene (ABS): Plastic material that is easy to shape and tough to break. Think LEGO’s, sunglass frames, replacement parts

Polylactic Acid (PLA) ranks as one of the most popular materials for 3D printing, particularly FDM. Its ease of use and minimal warping issues make PLA filaments the perfect starting point for 3D printing. PLA is also one of the most environmentally-friendly 3D printing materials and, unlike ABS, is biodegradable. Among other PLA advantages are also its low cost and a wide assortment of colours and blends. However, the brittleness of the material makes PLA more suitable for non-functional prototyping, decorative and low-stress applications.

Conductive Filaments: These printable materials are still in the experimental stage and can be used for printing electric circuits without the need for wires. This is a useful material for wearable technology and smaller electronics.

Flexible Filaments: Flexible filaments are bendable, yet tough. These materials can be used to print anything from wrist watches to cases. TPU is the most common for flexible material.

Metal Filament: Metal filaments come in steel, brass, bronze and copper in order to get the true look and feel of a metal object. KC Proto does not offer this type of printing.

Wood Filament: These filaments contain finely-ground wood powder mixed with a polymer glue.

Resins: KC Proto also offers 3d printing in a number of SLA resins.

Stereolithography (SLA) Technology is a fast prototyping printing type that is best suited for 3d printing products with intricate detail. Digital Light Processing (DLP) is one of the oldest forms of 3D printing, using lamps to produce prints at higher speeds than SLA printing because the layers dry in seconds.

Rapid Prototyping

3D printers are going to change the future, we are still learning how big of an impact that will be. Since 3D printers are incredibly flexible; not only in the materials they use, but also with what they can print we expect to see them used across every industry over the next decade. Today, many 3D printers are used for rapid prototyping, creating prototypes in a matter of hours instead of months. In fact, rapid prototyping can product prototypes 10x faster and 5x cheaper than traditional methods. This could potentially save millions of dollars in research and development.

The flexibility and adaptability of 3D printing technology makes it an instant game-changer. 3D printers can fill a role in virtually almost every industry from prototyping to finished product.

Healthcare - 3D printed parts for broken equipment, dynamic prosthetics, splints and more

Construction – replacement parts or tools to complete homes

Schools and Education - hands-on learning by printing three-dimensional dinosaur bones, robotics pieces, and educational crafts

Aerospace - functional prototypes, tooling, and lightweight replacement parts

Automotive – customized parts, tooling, engine components, and more

3D Printing Process

3D Modeling – Any object you want to print has to be designed in a 3D modeling software. Modeling allows printers to customize their product down to the tiniest detail. The 3D modeling software’s ability to allow for precision designs is why 3D printing is a true game changer.

Slicing the Model - Since 3D printers cannot conceptualize the concept of three dimensions each model needs to be sliced into layers to create the final product. Slicing software takes scans of each layer of a model and will tell the printer how to move in order to recreate that layer. Slicers also tell 3D printers where to “fill” a model. This fill gives a 3D printed object internal lattices and columns that help shape and strengthen the object.

3D Print - When the modeling and slicing of a 3D object is completed, it’s time for the 3D printer to do its job. The printing nozzle moves back-and-forth while dispensing a wax or plastic-like polymer layer-by-layer, waiting for that layer to dry, then adding the next level. It essentially adds hundreds or thousands of 2D prints on top of one another to make a three-dimensional object.

KC Proto currently has 49 3D printers that allow for batch printing and allows for prints to be split into smaller, quicker runs. We also offer laser cutting and CNC prototyping.

Request More Information

Fill out the form below and someone will contact you about your invention ideas, strategy, or needs. Your ideas matter so we prioritize your requests as soon as they come through! Most prints can be started within a few hours as we have 49 3d printers available. Unless otherwise requested, we typically print with a high resolution .12mm layer height with 4 perimeter walls and 30% infill. FDM printing is typically $.30 a gram with a $3.00 setup fee. We also have flexible pricing for larger prints and batch printing. Contact us below for more information and we’ll respond promptly with a quote.